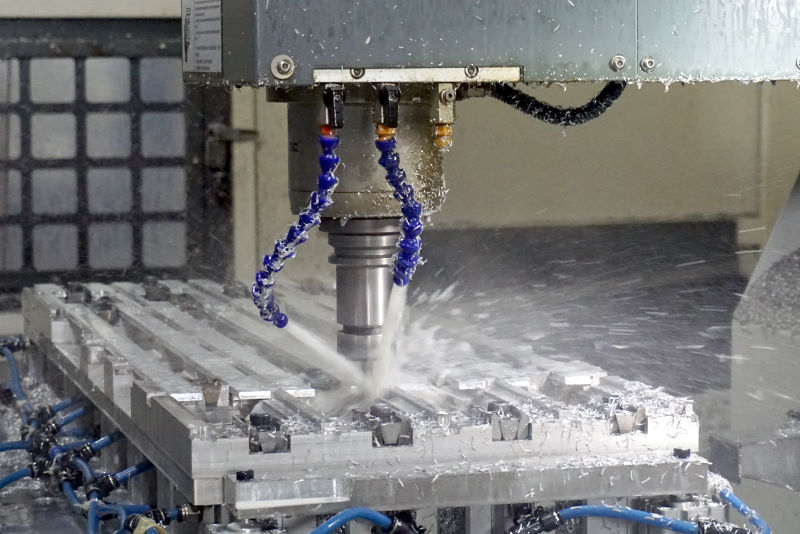

Aluminum alloys are a popular material choice for CNC machining because of their density and flexibility. Aluminum alloy machining meets both the precision needs of aluminum alloy machining and efficient production. At present, there are many kinds of aluminum alloys on the market. Which aluminum alloys are the most common for CNC machining? Shenghai Aluminum takes you to understand these five most popular aluminum alloys for CNC machining and detailed information about each alloy and its characteristics.

6061-T6

6061-T6 is one of the most popular aluminum alloys on the market and one of the standard grades for CNC machining. It balances strength and machinability well and usually very close tolerances. It is widely used and easy to process in the CNC machining industry. Engineers can use this alloy in many applications, such as automotive chassis, bicycle frames, valves, computer parts, etc.

7075-T6

Manufacturers of 7075-T6 aluminum use this alloy in all applications with high stress or high performance requirements. This grade has a fairly high strength and excellent corrosion resistance if properly processed. Manufacturers use this alloy in the aerospace and military industries, with typical applications including aircraft accessories, missile parts, and fuse parts. However, using aluminum 7075-T6 comes with a trade-off. It is more expensive and less flexible than many other grades of aluminum alloys. This grade of aluminum is also more prone to cracking and less elastic than other grades.

2024-T4

2024-T4 aluminum is a standard aluminum alloy used in sheets, plates, and profiles for various applications. This alloy is commonly found in applications where welding electrodes and components must have high purity and strength at high temperatures. The main use of 2024-T4 is as an aerospace material.

Typically, you can use this type of alloy to make aircraft fuselages, transport vehicle parts, and wing tension members. However, it can be attacked by acids, alkalis, or seawater. It also has high thermal conductivity, so it can be heat-treated to form an extremely brittle material.

MIC 6

It is the best alloy for producing stable and highly resistant sheet materials. Aluminum MIC 6 has a specific combination of alloy and casting methods, so it is unique. Compared to other aluminum alloys, this metal has a higher strength-to-weight ratio, excellent precision, good elasticity, and excellent thermal stability while remaining relatively easy to machine. This alloy also has a disadvantage. MIC 6 threads are not strong enough, resulting in early thread failure. As manufacturers, engineers should consider this limitation during the material selection phase.

6082

6082 aluminum has a high tensile strength. In addition, it also has excellent corrosion resistance. 6082 aluminum alloy is a good choice for manufacturers who want more power at an affordable price. 6082 aluminum is ideal for general-purpose applications that require higher toughness. Aluminum 6082 material is popular in construction and more suitable for bridges, towers, and trusses. However, product designers should remember that using 6082 aluminum to create thin walls is difficult.

Shenghai Aluminum has extensive experience in CNC machining aluminum, to learn more, please feel free to contact us.