Why is the precision of cutting aluminum profiles important?

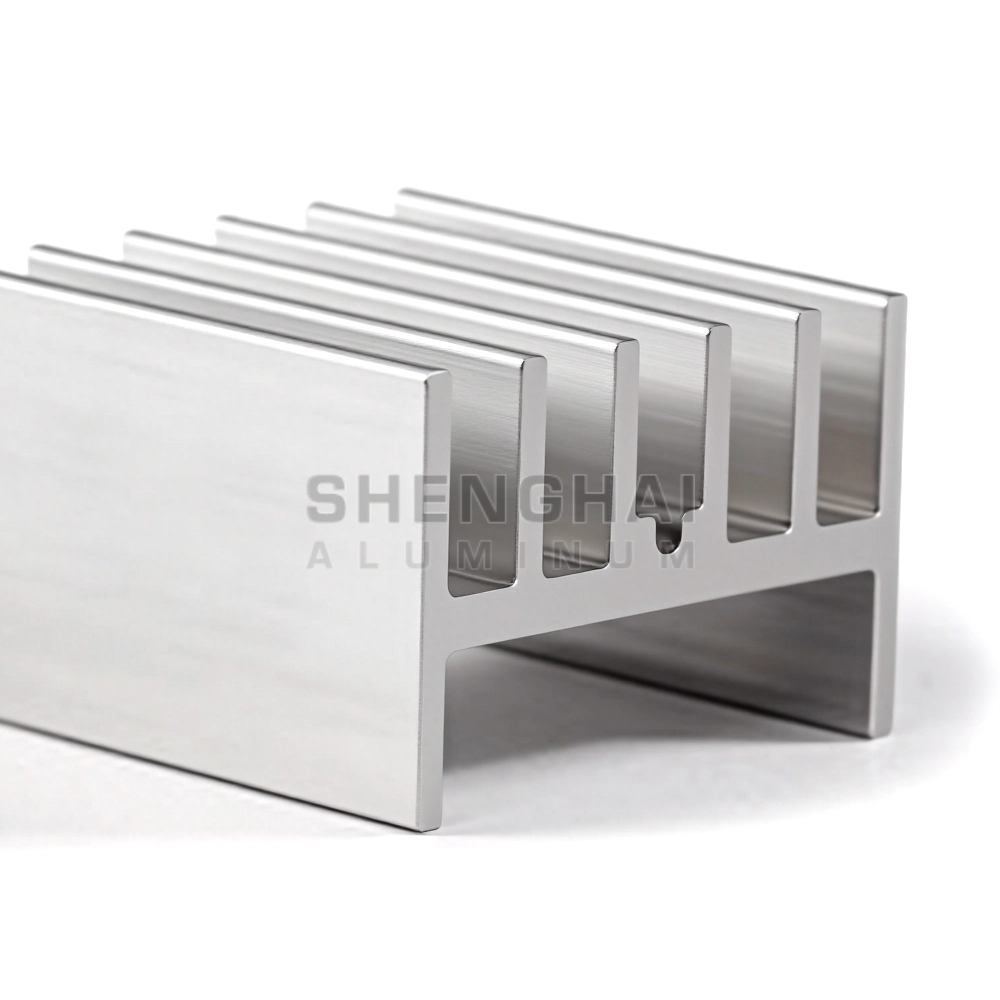

Aluminum profiles require very high cutting precision. In applications such as industrial automation equipment frames, electronic housings, and architectural decoration, the precision of each cut directly impacts the final assembly result. For our factory, this is paramount. Inadequate cutting precision can easily lead to excessive gaps in joints, misaligned screw holes, and unstable structures, resulting in material waste and increased costs. For buyers, selecting an aluminum profile supplier who can strictly control cutting tolerances is crucial to ensuring product quality and the smooth progress of projects. To this end, we place great emphasis on improving aluminum profile cutting precision.

Key Factors Influencing the Cutting Precision of Aluminum Profiles

The key factors affecting aluminum profile cutting accuracy can be categorized into four main categories, each of which can directly or indirectly impact the final cutting result at different stages:

1. Equipment Accuracy

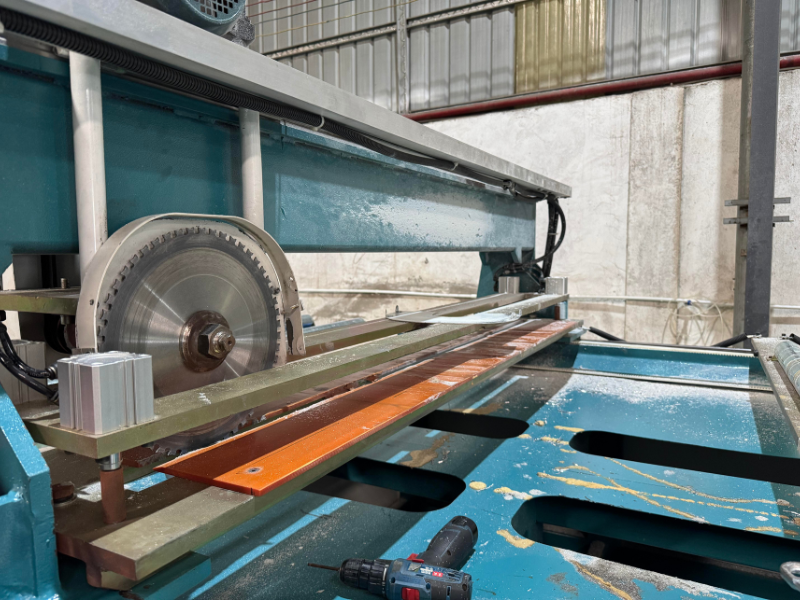

Differences in equipment accuracy can significantly impact cutting results. Conventional sawing machines are often insufficient for precise processing, whereas high-precision twin-head sawing machines or CNC cutting equipment can achieve cutting with a tolerance of ±0.1mm. High-precision twin-head sawing machines, with their dual-end simultaneous cutting and precise guide rail design, improve dimensional consistency. CNC cutting equipment, on the other hand, uses program-controlled automated precision positioning to further reduce human error, making it the preferred choice for high-precision cutting.

2. Tools and Saw Blades

The sharpness of tools or saw blades is essential for profile cutting. Blunt cutting edges can cause material to be squeezed during cutting, compromising accuracy. Materials should be optimized for the characteristics of aluminum profiles, such as specialized carbide or diamond-coated tools, to reduce wear and maintain cutting edge performance. Maintaining the sharpness of tools or saw blades also reduces edge deformation and burrs. Furthermore, using an appropriate coolant can reduce the local temperature during cutting, preventing softened aluminum chips from adhering to the cutting blade surface.

3. Process and Operation

Even with high-precision equipment, cutting errors are unavoidable if the process and operation are not standardized. Workers must correctly use fixtures to secure the profile to prevent movement or vibration during the cutting process. The accuracy of positioning methods is also crucial, such as clear reference points and the presence of auxiliary positioning tools, which can affect cutting accuracy. Our factory has a standardized operating process, and our experienced workers effectively improve cutting consistency and precision control.

4. Materials and Environment

The straightness and hardness of the aluminum profile itself can also affect cutting results. If the material has curvature or surface defects, even the most sophisticated equipment cannot completely eliminate errors. If the hardness is too low, deformation is easily caused by the tool being squeezed during cutting, while if it is too high, it may increase tool wear. Furthermore, a thick or uneven surface oxide layer increases cutting resistance, resulting in uneven cutting force and affecting the final dimensional accuracy. It’s worth noting that ambient temperature fluctuations can also cause aluminum to expand and contract, so maintaining stable environmental conditions is crucial for precision cutting.

Methods to Improve Aluminum Profile Cutting Precision

We’ve analyzed the factors that affect aluminum profile cutting accuracy. So, how can we resolve or prevent potential problems? We’ll introduce some effective methods based on practical experience.

1. Introducing High-End Equipment

To truly improve cutting accuracy, we need to invest significantly in hardware. For example, equipping fully automatic CNC cutting machines, double-head precision saws, or CNC centers can achieve automatic positioning and angle control, ensuring product stability and consistency in mass production.

2. Establishing a Comprehensive Tool Management System

Tools aren’t just a one-time investment; they require scientific maintenance. Establish a replacement cycle for saw blades and regularly check their sharpness and wear. Select tools that match different profiles to effectively minimize cutting errors. Furthermore, by properly utilizing the cooling system, you can further extend tool life and ensure a smooth cut surface.

3. Optimizing Processes

Improving cutting accuracy requires not only the right equipment but also effective scientific processes. We should establish clear cutting specifications, cutting speeds, and inspection procedures based on the requirements of different profile types and implement them into operators’ daily work. Standardized processes can minimize human error and improve overall efficiency.

4. Introducing Precision Inspection and Data Tracking

Cutting alone is not enough; inspection is key to ensuring accuracy. By introducing advanced inspection tools such as coordinate measuring machines and laser measuring instruments, we can monitor dimensional errors in real time and incorporate this data into our production tracking system. This not only identifies problems promptly but also provides a basis for subsequent process improvements.

5. Strengthening Personnel Training and Responsibility

Regular employee training to familiarize them with the characteristics of different aluminum profiles and cutting processes, while also fostering a sense of responsibility, can reduce errors at the source. The combination of an excellent operator team and advanced equipment can maximize the advantages of cutting precision.

Tips for Assessing the Cutting Precision of Aluminum Profile Suppliers

If you’re a buyer purchasing large quantities of aluminum extrusions, you might want to know how to determine which supplier is trustworthy. We’ll provide some guidance.

1. Check Cut Samples or On-site Inspection

Ask the supplier for cut samples or visit their factory. By checking the sample’s size, allowed differences, and the smoothness of the cut, you can easily judge how well the supplier can do the job.

2. Verify Technical Specifications and Processing Capabilities

Find out details like how much size difference is allowed, how many pieces they can make at once, and the smallest size they can cut. Compare these to what your project needs to see if the supplier is a good fit.

3. Consult After-Sales Service and Quality Commitment

Problems can happen during very precise cutting. It is important to check if the supplier has good support after you buy and promises good quality. Consider how they address mistakes or provide special services to mitigate your risk when making a purchase.

4. Reference Customer Cases and Industry Reputation

By examining a supplier’s past customer cases, especially their experience in high-precision industries such as automation equipment, electronics, and medical devices, you can assess their reliability and stability. Customer reviews and a long-term track record of partnerships are often more valuable than mere advertising.

Why Choose Us as Your Aluminum Profile Supplier

We offer a one-stop service from profile extrusion to further processing, supporting custom designs. We can also design cutting solutions tailored to your project needs, ensuring that every aluminum profile meets high precision standards. We also guarantee on-time delivery and comprehensive after-sales support, ensuring peace of mind for our customers. Contact us today to request samples or processing solutions.