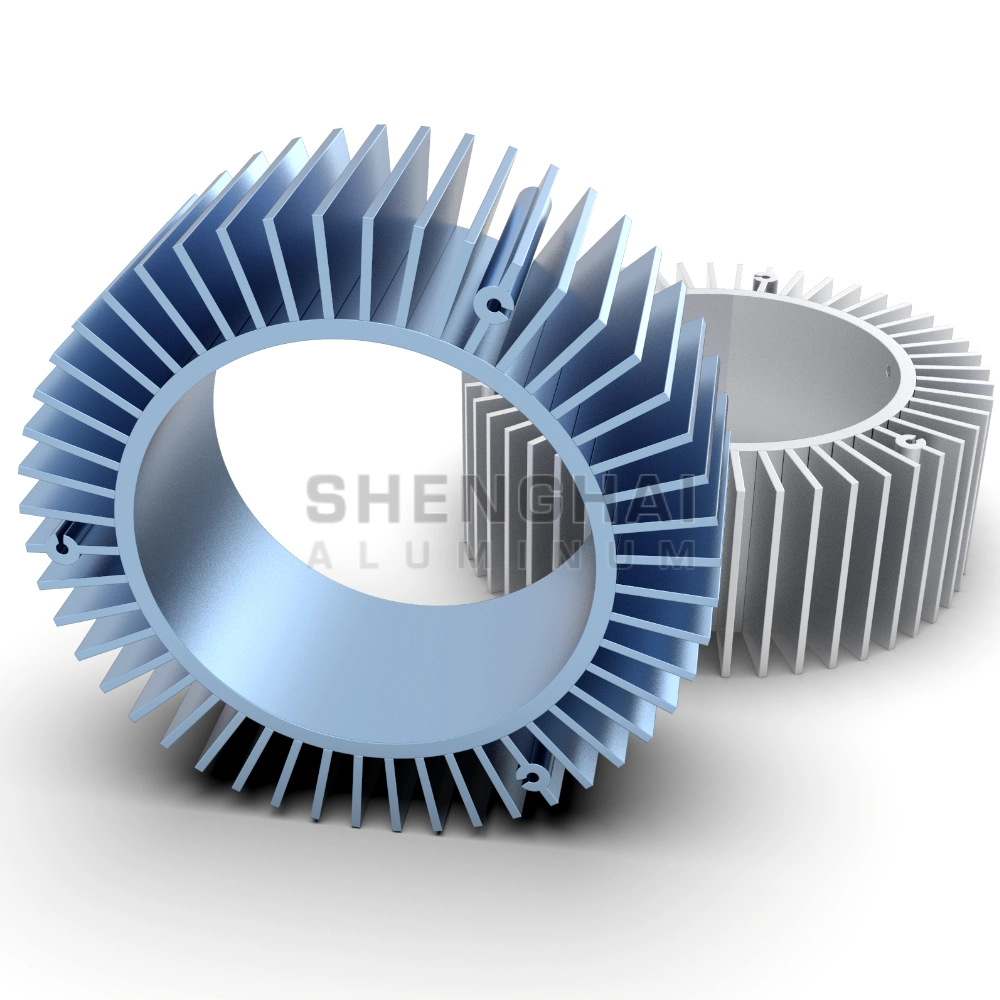

CNC machining aluminum profile, also called precision aluminum CNC machining, uses CNC equipment to achieve high precision. The processed aluminum profile parts have very high accuracy and a smooth surface. They meet the strict requirements of most industries and are now one of the most advanced and common methods in manufacturing.Let’s take a closer look at it.

Why is CNC machining the ideal choice for aluminum?

CNC machining is ideal for aluminum because of its high precision, good machinability, and ability to handle complex shapes efficiently. It ensures stable quality and supports many surface treatments, making it especially useful in aerospace and automotive industries.

High precision and consistency

Aluminum profiles parts need strict tolerances. CNC machining can reach ±0.01mm accuracy and ensure every part meets size requirements. This consistency is very important in industries like aerospace, where even small errors can cause failure.

Can process complex shapes

Aluminum is softer than many metals. Cutting it is easy. This makes tools last longer, lowers cost, and saves time.CNC machines have strong machining capabilities and can produce aluminum parts in many complex shapes. Whether it is curved surfaces, hollow sections, or special-shaped parts, CNC machining can handle them easily and meet diverse design needs.

Corrosion resistance

Aluminum naturally forms an oxide layer on the surface, giving it strong corrosion resistance. CNC machined aluminum parts can stay strong in different environments, with longer service life in fields like automotive and marine.

Cost efficiency and recyclability

Aluminum is cheaper than titanium or stainless steel but still has good mechanical properties. Aluminum can be recycled. Scrap from machining can be melted and used again. Concurrently, automated production reduces manual intervention and errors, thereby lowering manufacturing costs.

Multiple surface finishes

After CNC machining, aluminum can receive many finishes such as anodizing or powder coating. These improve appearance and add functions like better wear resistance or electrical insulation. This allows manufacturers to customize parts for different industries.

Aluminum combines high strength, light weight, and versatility. This makes it important in electronics, automotive, and aerospace. CNC machining effectively harnesses these properties of aluminum, making it the ideal choice for aluminum processing.

Main CNC Machining Processes for Aluminum Profiles

Cutting: Standard aluminum profiles are 6020mm long. To assemble frames, they must be cut into different lengths or angles. Precision saws or CNC cutting machines are used to ensure smooth and accurate cuts.

Drilling: Industrial production of aluminum profiles does not use electric welding. Connections are usually made with hardware, and different profiles require different connection methods. At the same time, various types of holes can be made, including countersunk and stepped holes. Drilling is a very common and technically advanced process in the CNC machining of aluminum profiles.

Tapping: Tapping aluminum profiles involves machining screw holes. During the process, threaded holes are machined at the ends according to design specifications to enable secure fastening of the frame in subsequent stages.

CNC milling: Milling uses a rotating cutting tool on the workpiece surface, moving along 3, 4, or 5 axes. Not always needed for standard frames, but required for custom parts or function expansion.

Advantages of Aluminum Profile CNC Machining VS Traditional Methods

Fewer fixtures: Fewer fixtures are needed to machine parts, especially those with complex shapes.Change part shapes and sizes by changing the machining program. This method works well for new products and redesigns.

Stable quality: High machining precision with excellent repeatability, achieving a maximum machining accuracy of ±0.01mm, ensuring dimensional accuracy with minimal error.

Efficient for small batches: Saves setup and inspection time, uses optimal cutting speeds, and improves delivery time.

Complex geometry: Can machine shapes that are hard or impossible to make with traditional methods.

Why Choose Our CNC Machining Services

We use multi-axis CNC machines, precision milling centers, and laser equipment. Our machines are rigid, and our workshop has temperature control to reduce thermal expansion and vibration errors. At the same time, we monitor every batch with CMM, laser scanning, and real-time data to ensure size, flatness, and surface finish all meet requirements.

Shenghai Aluminum is CNC machining services supplier. Choose us for cost-effective CNC machining aluminum profiles solutions that support diverse custom requirements and meet complex demands.