What Are Extruded Heat Sink Profiles

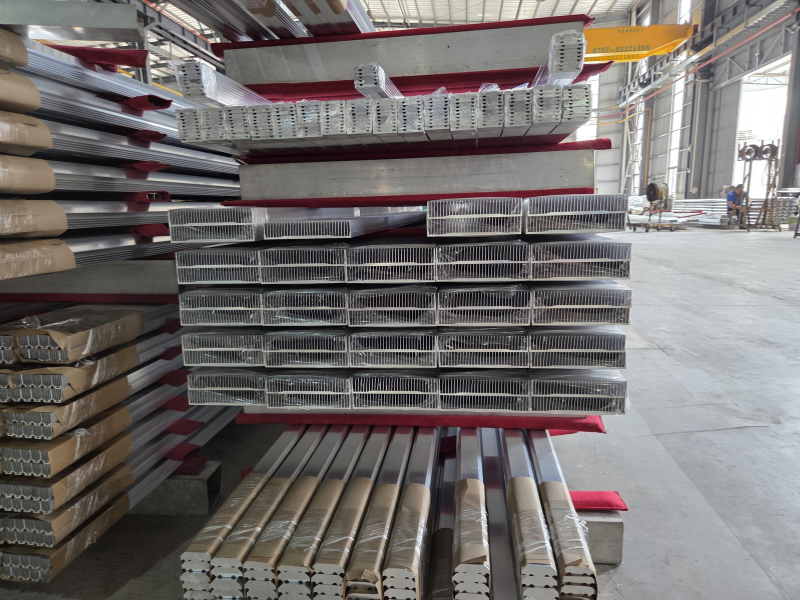

Among all cooling methods, extruded heat sink profiles have become one of the most popular and cost-effective solutions. These components are created through the aluminum extrusion process, where heated billets are forced through a precision die to form complex cross-sections that maximize surface area and airflow. Extruded aluminum heatsinks combine high thermal conductivity, lightweight structure, and great design flexibility. They are widely used in LED lighting, power supplies, EV charging systems, and telecom equipment.

As a result, extruded heat sinks are well suited for medium to large volume production, where consistent quality and cost control are crucial for us as suppliers.

Fundamentals of Heat Dissipation

For any heat source that cannot be effectively cooled by conduction itself, or requires higher heat dissipation efficiency, a heat sink is required. The design of a heat sink must consider the three basic modes of heat transfer: conduction, convection, and radiation.

- In a heat sink, heat conduction refers to the conduction of heat from the inside of an electronic component to the heat sink surface, as well as the conduction of heat within the heat sink. Heat flows from the heat source through the thermal interface material (TIM), into the heat sink base, and then spreads through the fins.

- Convection is the process of heat exchange between the fin surfaces and the surrounding air (or fluid). It can be natural (passive) or forced (using fans or airflow). Natural convection heat sinks maximize surface area and conduct heat without adding active components. Forced convection heat sinks are designed to use components such as fans and blowers to force cooler air across the fins, creating turbulence and increasing the heat sink’s cooling performance.

- Radiation transfers heat via electromagnetic waves, especially in infrared. Its effect is generally small compared to conduction and convection in typical electronics applications, but becomes more relevant at higher temperatures or when surface emissivity is high.

Why Choose Extruded Aluminum Heatsinks

Aluminum alloy was chosen for the heat sink because of its excellent thermal conductivity. 6063-T5 aluminum alloy, in particular, offers high thermal conductivity and excellent corrosion resistance.

Compared to copper, aluminum is lighter, easier to form into complex heat sink profiles through extrusion, and can be treated with a variety of surface treatments, such as anodizing, sandblasting, and brushing. At a fraction of the cost, aluminum can be used. While advanced materials such as copper and graphite composites or vapor chambers can achieve lower thermal resistance, they also come at a higher cost and weight.

When additional heat spreading or local hot-spot management is required, hybrid solutions combining aluminum bases with embedded copper inserts or heat pipes can deliver optimized results without excessive cost.

Key Geometric Factors in Designing Extruded Heat Sink Profiles

The geometry of a heat sink plays a crucial role in determining its thermal performance. For extruded heat sink profiles, engineers must balance fin dimensions, spacing, and base thickness to optimize both heat transfer and manufacturability.

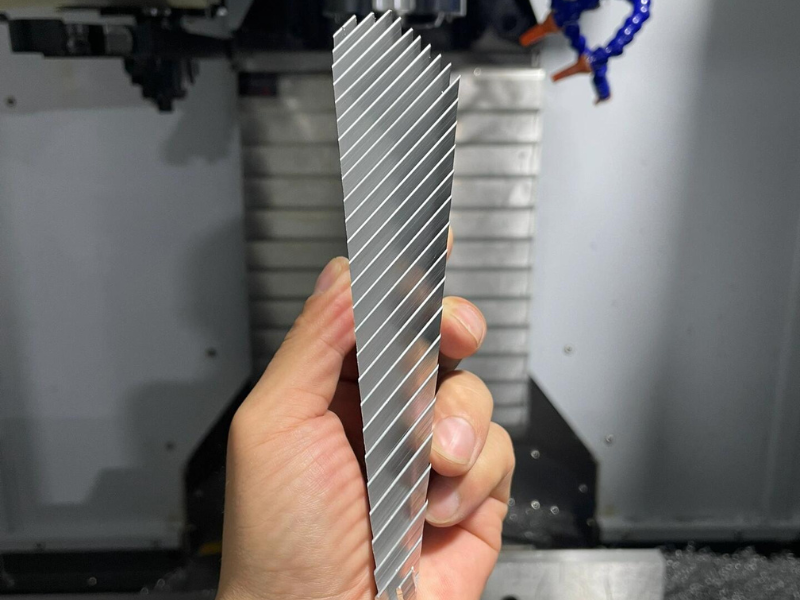

- Fin thickness affects conduction and extrusion feasibility. Thinner fins increase surface area but are limited by extrusion constraints and mechanical strength. For standard extruded aluminum heatsinks, the minimum fin thickness is typically around 1.0–1.5 mm, depending on the die design and alloy type.

- Fin spacing controls airflow efficiency. Too narrow a gap increases flow resistance and reduces convection; too wide wastes available space. For natural convection, fin spacing of 6–10 mm is typical, while 3–6 mm is preferred under forced-air conditions.

- Fin height determines surface area and pressure drop. Higher fins improve heat dissipation but may lead to uneven airflow distribution and higher extrusion stress.

- The base thickness should provide sufficient heat spreading without adding unnecessary weight or cost. A thicker base helps in distributing heat evenly, but excessive thickness adds thermal resistance and material cost.

By optimizing these geometric factors, designers can design an extruded aluminum heat sink that is suitable for their project.

Heat SinkTypes and Manufacturing Methods

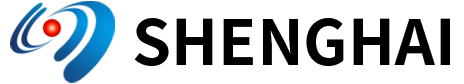

When designing extruded heat sink profiles, the manufacturing process significantly impacts cost, performance, and suitability. Heat sinks can be categorized by fin type as straight fins (plate fins) or pin fins, and by material type as aluminum or copper.

Extrusion

Extrusion is the most common method for producing straight fins. The desired cross-section is formed by pressing heated aluminum rods through a die. This method is cost-effective and can produce long, continuous profiles. Pin fin structures can also be approximated by cutting.

Forging

Forging is a manufacturing process that uses high pressure and temperature to transform metals such as aluminum or copper into the desired heat sink shape. Both pin fins and straight fins can be produced. Forged heat sinks offer superior grain structure and high thermal conductivity, making them suitable for high-strength and high-performance applications. However, this method offers limited design flexibility.

Stamping

Stamping is suitable for thin sheet metal straight fins, offering a quick and cost-effective method, but cannot be used for complex pin fins. It involves using a stamping machine to cut and form sheet metal into the desired fin shape.

Skiving

Skimming creates high-aspect-ratio straight fins by cutting thin sheets from a solid block. This method allows for tight tolerances, but is not suitable for pin fins.

Bonded fins

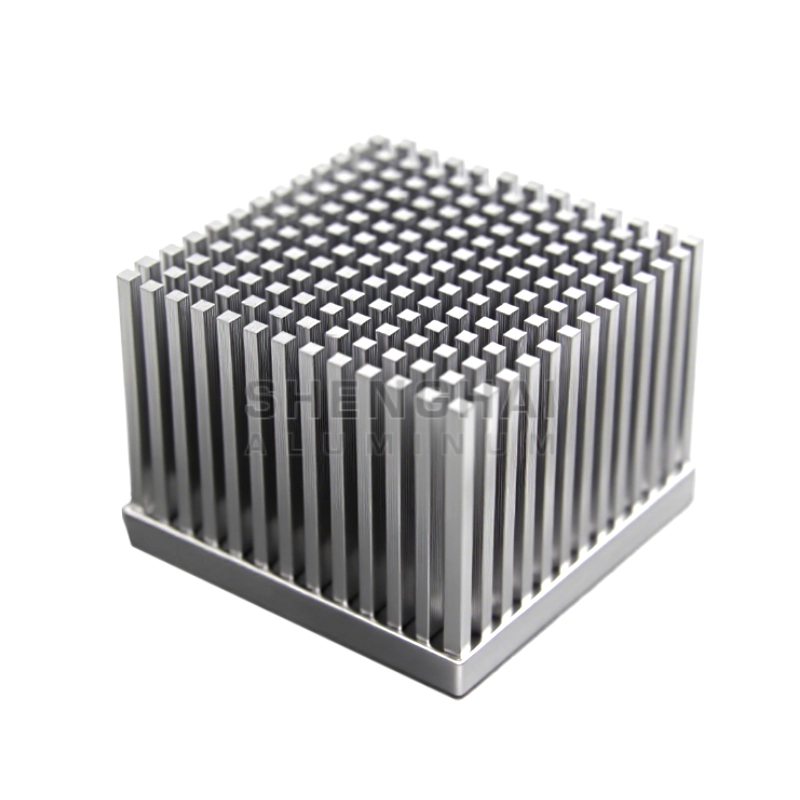

Bonding attaches individual fins to a base by gluing, brazing, or welding. This allows for complex layouts and is suitable for both straight and pin fins, but interfacial thermal resistance can reduce efficiency.

Zipper fins

Zipper fins create a high-density straight fin structure by folding thin metal sheets. They are suitable for forced air cooling, which is not possible with pin fins.

Selecting the appropriate process requires a balance between thermal performance, manufacturability, and cost. For most suppliers, extruded aluminum heat sinks offer the best performance, design flexibility, and production economics, making them suitable for medium to high-volume production.

Practical Design Checklist

For teams designing or purchasing extruded radiator profiles, we provide some practical design checklists to help you design better. Key points to consider include:

Material Selection: Confirm the alloy meets thermal conductivity, corrosion resistance, and weight requirements. 6063-T5 aluminum is commonly preferred for extruded aluminum heatsinks.

Fin Geometry: Check fin thickness, height, and spacing against extrusion capabilities and airflow requirements. Avoid dimensions below minimum wall thickness to prevent warping.

Base Thickness: Ensure sufficient heat spreading without unnecessary material or weight.

Surface Treatment: Select anodizing or powder coating as needed for corrosion resistance and aesthetics, ensuring surface emissivity is compatible with thermal goals.

Manufacturing Constraints: Verify extrusion die limitations, post-processing needs (CNC milling, tapping), and tolerances with the supplier.

Thermal Performance: Choose the appropriate surface treatment according to your needs, such as anodizing or powder coating, to improve performance while also taking into account aesthetics.

Assembly & Mounting: Plan mounting features, attachment points, and integration with other components.

By following this checklist, designers can reduce costly redesigns, ensure consistent quality, and accelerate production.

Shenghai Aluminum has extensive experience to ensure that extruded aluminum heat sinks maintain efficient heat dissipation and consistent quality in medium- to large-scale production. Professional guidance can be provided during the design stage to ensure reliable performance for all products. Contact our team to discuss your thermal management needs and obtain a customized quotation or sample solution.