Aluminum is one of the most used materials in mechanical machining. CNC machining of aluminum is used almost as much as steel.

Pure aluminum is soft, easy to bend, non-magnetic, and silver in color. Aluminum is usually not used in pure form. It is mixed with other elements like manganese, copper, or magnesium to make alloys. These alloys have better properties.

Advantages of Using Aluminum for CNC Machined Parts

Aluminum can be rapidly formed through various processing methods. Aluminum can be swiftly and easily machined by cutting tools due to its soft texture, machinability, affordability, and the reduced force required compared to processing steel. These characteristics offer significant advantages for both machinists and customers ordering parts. Moreover, aluminum’s excellent machinability means it is less prone to deformation during processing. It enables CNC machines to achieve higher tolerances, resulting in greater precision.

Easy to Machine

Aluminum can be shaped easily. It is soft, easy to cut, cheap, and needs less force than steel. This helps both machine operators and customers. Aluminum also keeps its shape well during machining. CNC machines can make parts more precise.

High Strength-to-Weight Ratio

Aluminum is about one-third the weight of steel, but it is still strong. High strength-to-weight ratio means it can carry more load for its weight. This is useful in cars and airplanes.

Corrosion Resistance

Aluminum does not rust easily in air or water. Anodizing can make it stronger. Different aluminum grades resist corrosion differently. Standard CNC grades often have the best resistance.

Low-Temperature Performance

Many materials get weak below zero degrees. Aluminum stays strong and flexible. This makes it good for cold containers, gas tanks, and airplane parts.

Electrical and Thermal Conductivity

Pure aluminum conducts electricity well. Aluminum alloys conduct less but are still good for electronics. Aluminum also transfers heat well. It is used in heat sinks, electronic cases, and heat exchangers.

Recyclability

CNC machining produces scrap metal. Aluminum can be recycled easily with little cost and energy. It is safe, flexible, and 100% recyclable. This is why it is used in food and drink containers, trays, lids, and packaging.

CNC Machining Methods for Aluminum

CNC Turning

In CNC turning, the part spins while a cutting tool stays mostly in place. Tool and part move to remove material. This is good for round parts and shafts.

CNC Milling

CNC milling is the most common way to machine aluminum. A rotating cutting tool removes material from a part. The part can stay still or move. Multi-axis milling can make complex shapes.

Slot Milling: Makes grooves on the part. Can use milling, turning, or boring.

Face Milling: Makes a flat surface on the end. Used for shafts, sleeves, and discs.

CNC Drilling

CNC drilling uses a rotating multi-point tool to create precise holes. The tool moves linearly perpendicular to the surface.

Tool Selection for Aluminum CNC Machining

Number of Flutes

Aluminum tools usually have 2 or 3 flutes. Two-flute tools remove chips fast. Three-flute tools balance chip removal and tool strength.

Helix Angle

Helix angle changes how chips leave and heat forms. Roughing: 35–40°. Finishing: 45° for smoother surface.

Relief Angle

Best relief angle: 6–10°. This reduces friction and keeps surface smooth.

Tool Material and Coating

Carbide tools are best. Small grains make the tool strong and tough. Coatings like ZrN, TiB₂, or diamond-like layers stop chip build-up and last longer.

Cutting Speed and Feed Rate

Aluminum can be cut fast. Feed rate depends on rough or fine cut: 0.15–2.03 mm/rev for roughing, 0.05–0.15 mm/rev for finishing.

Coolant Selection

Do not cut aluminum dry. Use oil-based or mineral oil coolants. Avoid chlorine or sulfur fluids.

Post-Machining Processes

Peening and Sandblasting

These clean and smooth the surface. They can make the surface shiny or matte.

Coating

Zinc, nickel, or chrome coatings improve the surface.

Anodizing

Anodizing uses electricity in acid to make a hard aluminum oxide layer. It can also add color.

Powder Coating

Powder is sprayed on and heated to 200°C. This makes the part stronger and protects against wear and rust.

Heat Treatment

Some aluminum alloys can be heat treated to improve strength.

Industrial Applications of CNC Machined Aluminum

Aerospace: Strong and light, used in airplane parts.

Automotive: Used for shafts and other parts.

Electrical: Used for electronic parts.

Food & Pharmaceutical: Does not react with food, used in machines.

Sports: Used for bats, whistles, and other equipment.

Cold Applications: Works well below zero.

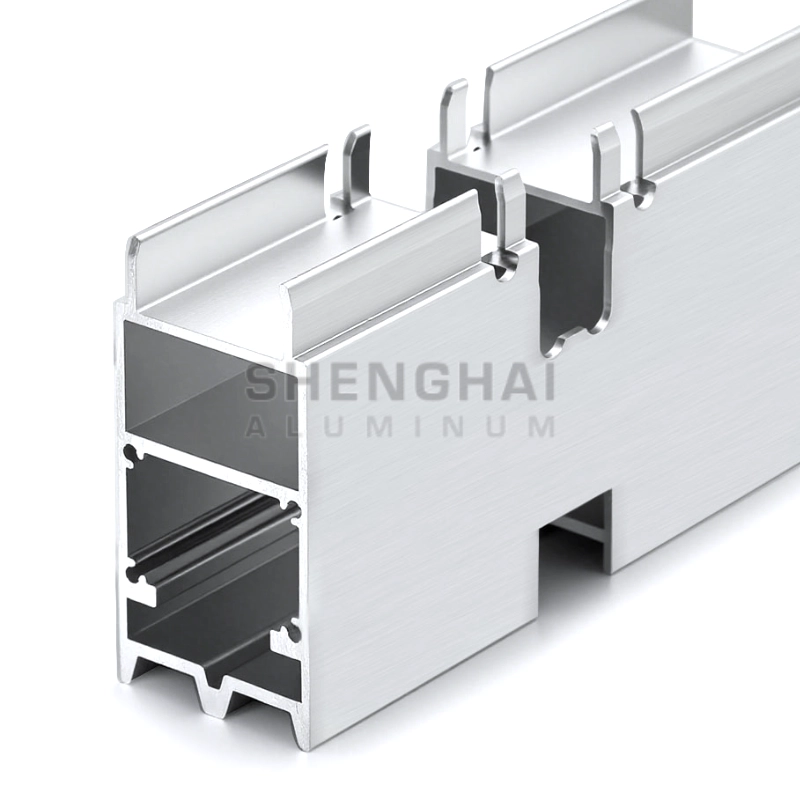

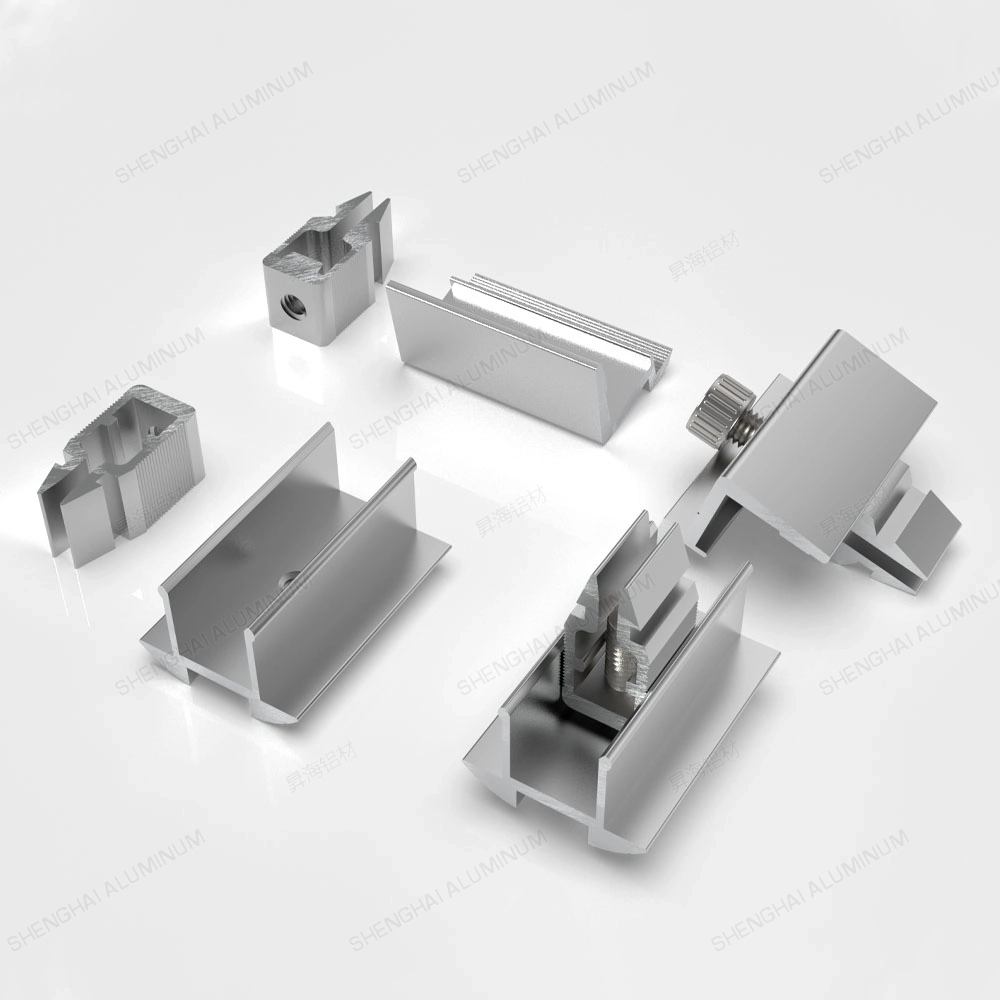

Why Choose Us for Aluminum CNC Machining

Shenghai Aluminum has over 15 years of experience. We have precise machines and skilled engineers. We machine many aluminum alloys and provide custom CNC machining for aluminum profiles. We check quality carefully and offer flexible order sizes: samples, small, or large batches. Contact us for professional aluminum CNC machining solutions.