Aluminum is a universally beloved metal material, boasting excellent processing properties and a relatively low price, making it highly suitable for machining. The processing of aluminum profiles from raw material to finished product involves more than simple cutting or forming; rather, it involves a comprehensive process involving extrusion, heat treatment, surface treatment, and CNC machining. This process is crucial for ensuring the mechanical properties, precision, and surface quality of aluminum profiles. If cost optimization or efficiency improvement is required, it should also start with refining and optimizing this stage of the process. Furthermore, manufacturers can process aluminum three to four times faster than other commonly machined materials, such as steel and titanium.

This article will provide a detailed overview of the aluminum profile processing process, providing a comprehensive understanding of the professional aluminum processing process and helping buyers make informed decisions when sourcing and customizing aluminum profiles.

What Is Aluminum Fabrication

Aluminum fabrication is the key step in transforming raw aluminum or aluminum alloy materials into a variety of usable products, such as familiar aluminum trim, door and window profiles, and automotive parts. Essentially, aluminum fabrication involves modifying aluminum and aluminum alloy billets through a series of physical, chemical, or mechanical processes. This involves altering their external form, such as from blocks to profiles, sheets, and tubes with specific cross-sections, and finally to sophisticated components. It also involves optimizing their internal properties based on application requirements, such as increasing hardness through heat treatment and enhancing corrosion resistance through surface treatment.

What is aluminum extrusion process

Among the many excellent processing methods, aluminum extrusion is the core means of maximizing aluminum’s processing properties. The principle of this process is simple: simply put, it uses external force to force heated aluminum alloy billets through a specifically shaped die hole, shaping the original block of aluminum into products with various cross-sections, such as tubes, profiles, and wire.

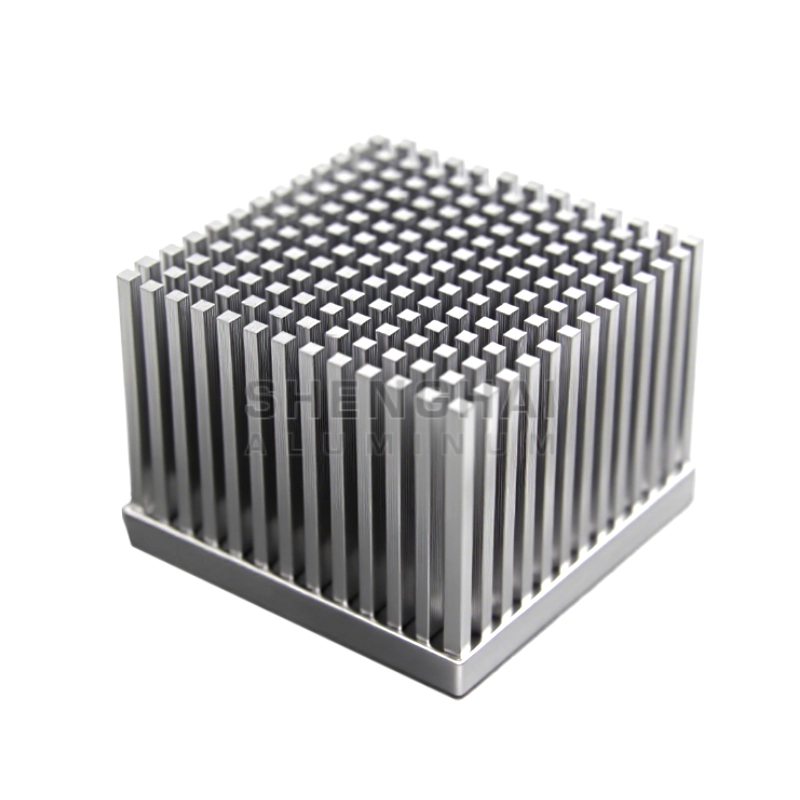

What’s more worth mentioning is that the aluminum extrusion process can also retain the original characteristics of aluminum to the greatest extent. Aluminum products that have been extruded are not only stronger and more ductile, but also have excellent corrosion resistance, which makes them excellent in many fields. In the construction industry, aluminum alloy profiles produced by aluminum extrusion are light and strong, making them ideal materials for doors, windows, and curtain walls, which not only reduces the weight of the building but also extends its service life. In the field of transportation, many of the aluminum alloy frames of automobiles and lightweight components of high-speed railways are manufactured through aluminum extrusion, which effectively reduces energy consumption and promotes green travel. Even the heat dissipation components in electronic equipment rely on high-precision profiles created by aluminum extrusion to ensure stable operation of the equipment.

What is heat treatment?

After aluminum extrusion is formed, the material’s hardness may not meet project requirements. To enhance the aluminum profile’s mechanical properties, stability, and durability, it is typically subjected to heat treatment and aging. This process enhances the profile’s strength, hardness, and lifespan. Heat treatment is not a simple process of heating followed by cooling. Instead, it involves precisely controlling temperature and cooling rates to alter the grain structure within aluminum alloys, thereby achieving their desired physical and mechanical properties.

What is CNC machining

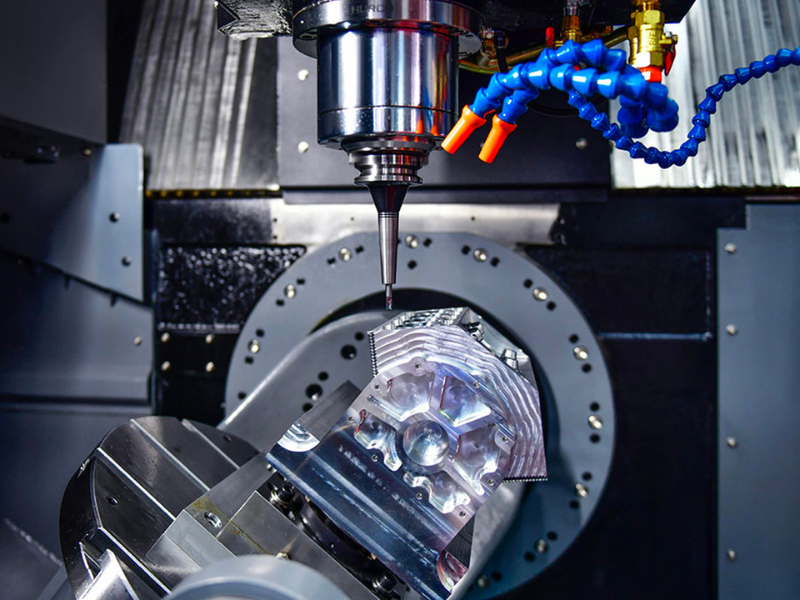

CNC machining, or Computer Numerical Control (CNC), refers to the use of computer programs to control machine tools for the precise machining of various workpieces. Pre-programmed instructions control key machine parameters such as tool trajectory, speed, and feed rate, enabling high-precision machining of workpieces. This technology effectively improves machining efficiency and product accuracy, meeting the demands of fine machining of complex workpieces. This technology meets the needs of mass production of standardized workpieces and is widely used within the industry.

Core Methods of CNC Machining

- Milling: Using a rotating milling cutter to cut the surface or interior of aluminum parts can produce structures such as planes, grooves, steps, and special-shaped contours. It is often used for the shape and detail processing of aluminum housings, frames and other parts.

- Drilling: Using a drill bit to create a circular hole of a specific diameter and depth in aluminum parts is a fundamental and common process in aluminum machining. It is widely used in aluminum parts that require fasteners (such as screws and bolts) to ensure precise hole placement and uniform diameter.

- Turning: The aluminum part is mounted on the machine tool spindle and rotated at high speed while the tool moves along the part’s axis or radial direction. This process is primarily used for machining rotationally symmetrical aluminum parts, such as cylindrical and conical shapes, such as shafts and sleeves. The finished aluminum part achieves a highly smooth surface.

- Tapping: Internal threads are created within a drilled aluminum hole. The rotary tap forms a thread that meets specifications, facilitating the connection between the aluminum part and other externally threaded parts. This process is commonly used in the connection of aluminum brackets and accessories.

What is aluminum profile surface treatment

Aluminum profile surface treatment refers to the process of treating the aluminum profile’s surface through physical, chemical, or electrochemical means after it has been extruded and formed. Its core purpose is to improve the profile’s surface properties and appearance, making it more suitable for various applications.

Common treatment methods include anodizing, electrophoretic coating, spraying, and brushing. These processes not only extend the profile’s lifespan but also impart a variety of aesthetic effects and even add special features such as electrical conductivity and thermal insulation. Therefore, aluminum profiles are widely used in construction, automotive, electronics, home furnishing, and other fields.

Assembly, Inspection and Quality Control

After completing the aluminum processing, we also need to inspect and assemble to see if it meets the export standards. The inspection process usually focuses on the accuracy and appearance of the product. By measuring the dimensions, the length, width, height, aperture and other key data of the profile are checked to ensure consistency with the design drawings. For the appearance, visually or with the help of instruments to detect whether there are any defects on the surface. At the same time, attention should also be paid to whether the tolerance verification is within the allowable range to prevent the subsequent assembly from being affected by insufficient accuracy. For aluminum parts that need to be assembled, we will use appropriate screws, bolts and other fasteners to fix the profiles according to needs. Sometimes, some aluminum parts will be embedded with plastic inserts to enhance the stability of the connection. Finally, professional packaging is used to protect the product to prevent damage during transportation.

Why choose us as your right aluminum processing partner

Shenghai Aluminum is a leading aluminum profile supplier specializing in integrated extrusion, deep processing, and surface treatment services. Our advanced equipment and comprehensive engineering system ensure stable supply and guaranteed quality. We offer not only reasonable pricing but also professional customization services. Contact us today for a quote and solutions for your project!