Aluminum profiles are a metal material with many advantages. They can be found in many aspects of daily life, such as doors and windows, ceilings, aluminum solar profiles, and heat sinks. The aluminum profiles used in these applications are produced through extrusion and require a series of aluminum deep processing steps to obtain aluminum alloy products with diverse colors, hardness, corrosion resistance, and high dimensional accuracy.

What Is Aluminum Deep Processing?

Aluminum profiles after extrusion are not considered complete products, they require a series of deep processing techniques to complete production.Aluminum deep processing involve further processing of semi-finished aluminum alloys, such as processes to ensure precise dimensions, adjust bending angles, and create protective surface layers. These are all part of the deep processing of aluminum profiles.

Applications

Thermal break aluminum doors and windows: The door and window frames require precise cutting to fit the door size. Only with precise dimensions can secure assembly and structural stability be ensured. They utilize a complex hollow structure filled with thermal insulation strips, forming the core design of thermal break aluminum door and window frames, combining thermal insulation, heat preservation, and robustness.

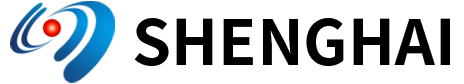

Heat sinks: The core function of a heat sink is thermal conductivity. Deep-processed aluminum has high thermal conductivity, as well as corrosion resistance and a long service life, making it ideal for heat sinks. The natural oxide film on aluminum profiles is thin, resulting in low thermal radiation efficiency and insufficient heat dissipation. Deep processing through anodizing significantly improves the heat dissipation performance of aluminum profiles.

Aluminum solar profiles: Solar panels are constantly exposed to the elements, including rain, UV radiation, high temperatures, and strong winds. Therefore, aluminum profiles need aluminum deep processing to mitigate environmental impacts. Anodizing is one such deep processing technique, significantly improving corrosion resistance and surface hardness.

- Aluminum Heat sinks

- Photovoltaic aluminum panels

- Durable automotive aluminum part

Reasons For Aluminum Deep Processing

The functionality of extruded semi-finished aluminum profiles is not diverse, their performance is relatively uniform, belonging to standard aluminum profiles. Some applications require aluminum profiles with stronger performance to meet the demands, such as aluminum doors and windows, solar aluminum profiles, curtain walls, heat sinks, and automotive aluminum profiles.

Aluminum profiles must be cut to precise dimensions, especially for applications like heat sinks and automotive aluminum profiles. The surface of aluminum profiles must be treated to provide environmental resistance, such as corrosion resistance against rain and salt spray environments (e.g., doors, windows, curtain walls, solar panels), and surface hardness to resist scratches and impacts (e.g., aluminum frames for public building doors, aluminum handrails).

What Are The Deep Processing Techniques?

CNC Precision Machining

This is a processing method that uses computer numerical control (CNC) technology to control the machine. The processed aluminum profiles can have high precision and complex structures. CNC machining processes include drilling, milling, stamping, cutting, tapping, CNC machining, bending, etc.

Surface Treatment

Surface treatment can significantly improve the surface hardness and corrosion resistance of aluminum profiles, and provide a more aesthetically pleasing appearance, enhancing the visual value of the aluminum profiles. Common surface treatment methods include: powder coating, anodizing, wood grain transfer printing, electrophoretic coating, sandblasting, polishing and brushing, fluorocarbon spraying, chemical oxidation, etc.

Welding

Welding refers to the process of connecting multiple aluminum profiles under high-temperature conditions to change the overall appearance and increase their functionality. Its essence is the use of the high thermal conductivity and easy oxidation properties of aluminum profiles to achieve fusion or solid-state connection. Some commonly used methods include TIG welding, MIG welding, laser welding, and friction stir welding.

Forming Process

The forming process is a key step in aluminum extrusion, determining the specific shape of the aluminum alloy, including extrusion molding, stretching and straightening, and stamping and drawing.

Manufacturing

The processing of aluminum doors and windows is also considered aluminum deep processing, such as cutting, drilling, filling with thermal insulation strips, and hardware installation during the assembly of thermal break aluminum doors and windows.

CNC machine

Aluminum Profile Deep Processing Manufacturers

Shenghai Aluminum is an aluminum profile manufacturer located in Foshan, Guangdong, China. In addition to common aluminum extrusion processes, we also have many aluminum deep processing techniques, among which CNC precision machining and surface treatment are our main technologies. These two technologies are relatively mature, improving the quality of our products and significantly increasing production volume.