Aluminum extrusion profiles are widely used in various sectors, such as construction, transportation, electronics, and renewable energy. The outstanding material characteristics of aluminum make it a good option to engineers and manufacturers. Nevertheless, in a large number of applications, these profiles are not straight, but must be bent or shaped into complex geometries. It is not as easy to bend extruded aluminum as it looks. Mishandling may lead to cracks, surface defects, dimensional errors and high levels of spring back.

Selecting the appropriate bending process is crucial for achieving accurate aluminum extrusion bending and maintaining cost control. Some of the most common extruded aluminum bending processes that are applied in the industry will be discussed below.

Key Factors Affecting Aluminum Bending

It is worth knowing the factors that affect the performance of aluminum extrusions after bending before introducing common methods of bending. These factors often determine whether the formed profile meets customer performance and appearance standards. Before this, let me briefly explain that bending performance refers to the ease of bending an aluminum extrusion and the quality of the finished profile.

Alloy Type

Aluminum alloys are subdivided into various grades typically as series. Form ability, ductility, and strength vary among the series. As an illustration, 6000-series alloys (e.g. 6061 or 6063) are popular in construction and industrial applications due to their good corrosion resistance, moderate strength, and good bend ability. By comparison, the alloys in the 7000-series are stronger yet they are more likely to crack on bending. Therefore, we also need to pay attention to which alloy series to choose for bending.

Profile Design

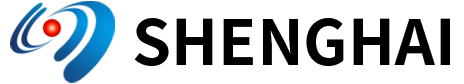

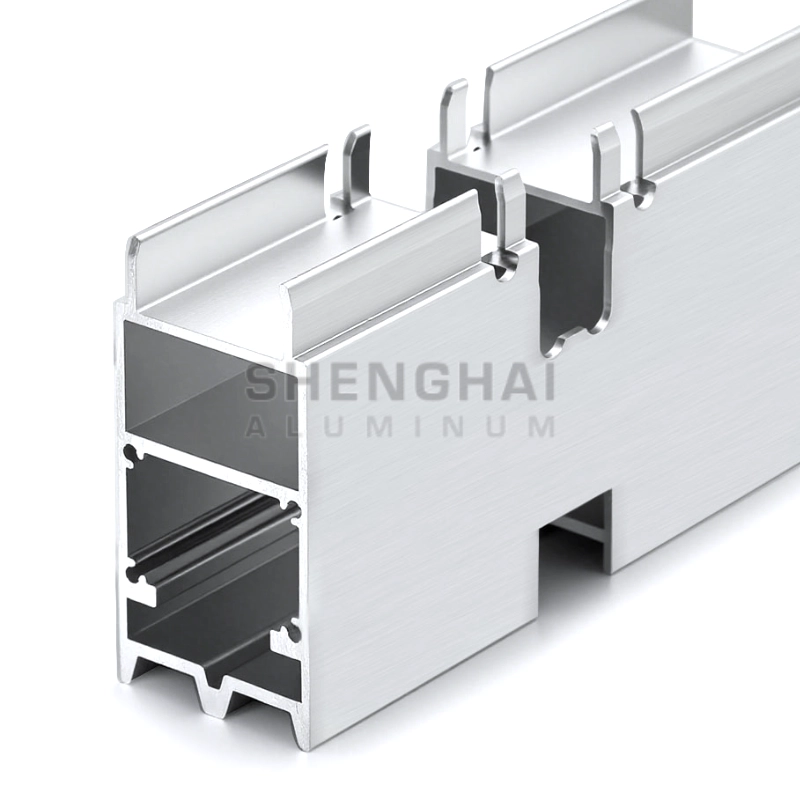

Hollow forms, solid walls, or elaborate multi-cavity constructions may make bending difficult or result in non-uniform deformation. Bend ability is greatly influenced by the cross-sectional geometry of the extrusion. Plans are less complex, uniform and supported by a symmetry are usually more stable under bending.

Bend Radius and Angle

The smaller the bend radius, the greater the risk of surface cracking or profile deformation. As a general rule of thumb, the minimum bend radius should be at least three times the wall thickness, but this can vary depending on the alloy family and bending method. Large bends also increase the risk of spring back.

Surface Treatment

Anodizing, powder coating or painting may be damaged in the process of bending. Surface treatment should generally be avoided before bending unless the coating is specifically designed to withstand deformation. This will make sure that the end product has the intended look and corrosion resistance.

Temper Treatment

Tempering improves the alloy’s physical properties, making bending more difficult and expensive. Therefore, it’s best to perform a full or partial tempering after bending.

By carefully considering these factors, We are able to improve the extrusion design and the corresponding bending method to minimize the number of defects and provide consistent quality.

6 Common Methods to Bend Extruded Aluminum

Roll Bending

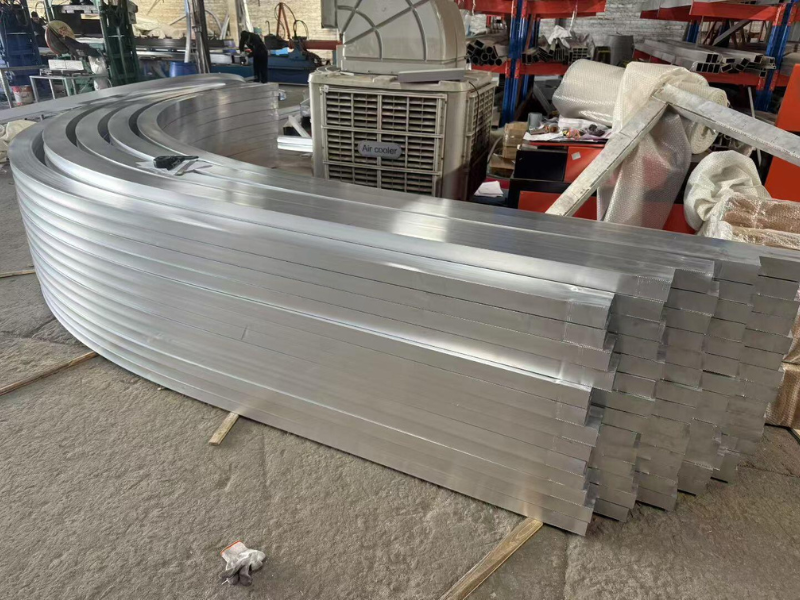

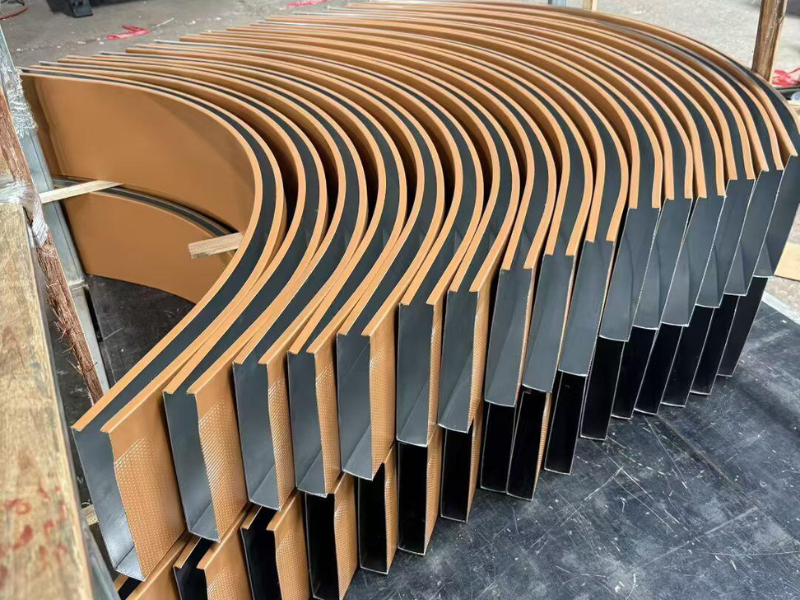

One of the most common methods for bending long profiles is roll bending. Incremental bending of aluminum profiles to the required radius is accomplished using a roller sequence of adjustable rollers. The distance of the rollers and their tilt angles are used during the process to regulate the amount of bend. The rotation of the rollers generates the required amount of friction, which moves the profile forward.

Its strengths are that it can be used well to bend long profiles and with profiles that need large radii. It is also economical when production volumes are medium and large scale. Roll bending can also be used to reduce the amount of surface damage to aluminum profiles with experience and proper set up.

Naturally, there are drawbacks.When the radius is very small (sharp bends), the profile too thin, or the cross-section irregular or multi-cavity, the material is prone to creasing, flattening, cracking, or distortion leading to uneven wall thickness. In addition, complex profiles requiring very fine angles or precise curvatures may struggle to achieve dimensional consistency through roll bending alone.

Press Brake Bending

This method typically uses a hydraulic or mechanical press brake to bend the aluminum profile between a punch and a V-shaped die. This process can be completed in a single pass or in multiple stages to achieve complex bends. The punch applies force directly to the profile, deforming it along the bend line, while the die supports the material and maintains the desired angle.

The working principle of this approach allows using it with both simple 90-degree bends as well as complex and step-by-step bends to guarantee the accuracy of angles and tolerances. It is able to bend easily shorter profiles that are hard to bend using roll bending.This method offers lower costs for applications requiring frequent die changes for varying profiles or for small batches. However, it’s important to note that this method has very strict restrictions on profile geometry; profiles that are too wide, hollow, or thin-walled may be prone to deformation.

Stretch Forming

Stretch forming is a process that uses clamps to hold the ends of an aluminum profile, stretches it to a specified tension and is then rolled around a forming die to form a desired shape. Since the profile is continuously strained in the bending process, the material is uniformly strained thus minimizing distortion and producing a clean, accurate curve.This method can achieve large, complex curves that are difficult to achieve with other methods. However, this method is costly and unsuitable for low-volume production or very small parts.

Mandrel Bending

Compared to other methods, Mandrel Bending has more limitations. It is a bending method designed specifically for hollow or tubular aluminum profiles. During the bending process, a solid or flexible mandrel inserted into the tube supports the inner wall. Meanwhile, scrapers and dies help guide the outer wall. This internal support prevents the tube from collapsing, wrinkling, or losing its round shape when bending to the desired angle or radius. A corresponding mandrel is however necessary with every profile size making it expensive. Optimal results may be achieved through applying lubricants and surface protectors that may be used to reduce friction and avoid scratches.

Heat Bending

Heat bending refers to the local heating of aluminum profiles before applying bending force to increase their ductility.Higher temperatures (usually 150degC to 400degC depending on alloy and thickness) make the material more flexible and the material can bend, but does not crack or break. When it is cooled, the extrusion assumes the shape desired.

This is an easier way to form hard to form alloys and is best used with high strength alloys or with thick-walled extrusions that tend to crumble when cold-bent. Nevertheless, it also demands additional processing time, more rigorous control of the process, accurate temperature control and equipment.

CNC Bending

CNC bending involves bending aluminum profiles with great precision using a computer controlled press or press brake. CNC technology eliminates human error and enables some complicated bending programs to be carried out on a single part as compared to manual or semi-automatic press brakes. The machine is programmed in a manner that it follows a pre-determined set of parameters which include the bend angle, radius, force and sequence which not only makes it accurate and repeatable.

Its benefits are that it is efficient and can be multi-stepped bended without having many molds. Every bend has the same programmed angle, and it is therefore suitable in projects that have narrow tolerances. Nevertheless, this approach is associated with a huge start-up cost, not just in the cost of the machine, but also in the expertise of the operators, which does not suit the manufacturers of small batches.

Future Outlook: Extrusion-Bending Integration

The current bending method of aluminum involves mostly two steps of bending, which include extrusion of straight profile then bending it into the desired shape. Nevertheless, integrated extrusion-bending technology is being investigated by researchers and manufacturers. The developed process integrates extrusion and bending into one continuous process that leaves the profile with a desirable curved shape when it is out of the die.

It is more efficient and precise than the conventional means and allows creating more complicated curved profiles at a reduced cost. Integrated extrusion-bending technology is however in development and poses numerous challenges. Nevertheless, it is believed to be a promising trend in the future in aluminum forming technology.

In Shenghai Aluminum, we are keeping a close eye on these new technologies and provide you with various aluminum profiles and bending solutions that will address your project requirements today.Get in touch with us and tell us about your needs and expert advice about the most suitable bending solution to your project.