Quality assurance

Shenghai provides ODM and OEM services to customers. We provide a series of services such as design review, mold development, aluminum profile extrusion, finishing, packaging and delivery. From raw material procurement to every link of the production process, each batch of products undergoes rigorous testing and auditing to ensure compliance with international quality standards.

team service

With over 15 years of experience, we guarantee to provide customers with product designs that are in line with local market usage habits and low cost. We have a professional customer service team to ensure timely response and processing of every customer’s needs. Whether it is product technical support or after-sales problems, we provide comprehensive solutions.

Standard production process

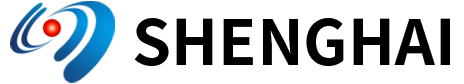

01 Extrusion profiles

The die is designed and manufactured according to the cross-section of the profile product, and the heated aluminum ingot is extruded by the die through the extruder.

02 Aging Treatment

Aluminum alloys may need to be heat treated to change their mechanical properties.

03 Cutting

Aluminum alloys or aluminum products are cut into desired shapes and sizes by physical or chemical methods.

04 Surface treatment of aluminum

The profiles are transported to a specialized workshop for surface treatment such as anodizing.

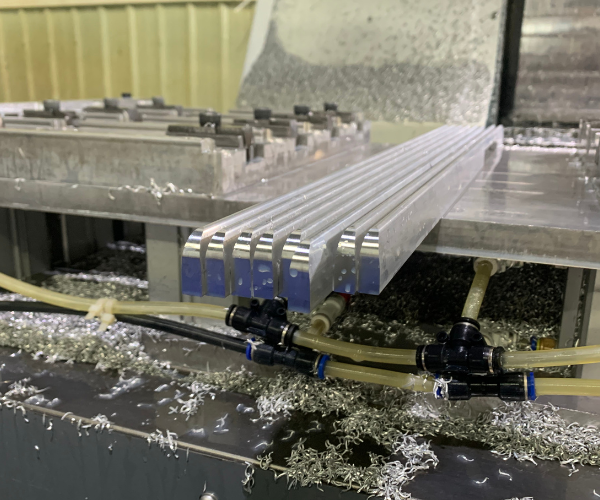

05 Processing

After the aluminum material is formed, deep processing such as cutting, drilling, stamping, welding, etc. is carried out according to requirements.

06 Inspection and packaging

Aluminum products are inspected to ensure that their quality meets the standards. Then they are packaged and prepared for shipment or storage.